Formlabs on Thursday confirmed that it has laid off a “small number” of employees, TechCrunch has exclusively learned. The 3D printing firm says the figure amounts to less than 40 of a total headcount of just under 750 employees.

The layoffs occurred in waves over the past two years, and as recently as the last few weeks. A spokesperson for the company confirmed the staff reduction. In a statement to TechCrunch, the spokesperson noted:

We routinely review every part of the organization to make sure the roles we have best support our customers and enable us to deliver great products. At the same time, we are hiring new roles across all divisions and geographies and are heavily investing in R&D. While we continue to grow revenue and lead in the additive manufacturing market, we occasionally must make the difficult decision to part ways with a small number of colleagues who are in departments that are below our efficiency goals and/or who are not in the right roles.

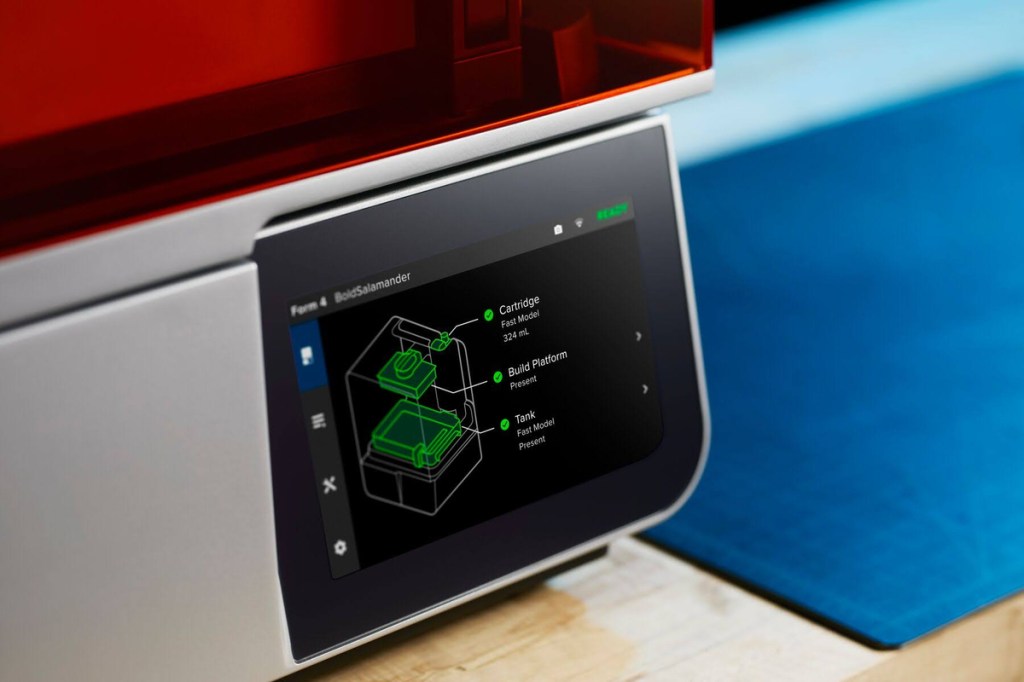

The MIT spinoff has been a rare success story in the 3D printing market, as the first to bring high-precision SLA (stereolithography) printing to the desktop form factor. Prior to its arrival, that corner of the market was almost exclusively made up of FDM (fused deposition modeling) printers, which deposit melted plastic layer by layer, in a manner similar to a hot glue gun. SLA, meanwhile, uses light to form a resin into a solid, high-resolution structure.

Formlabs weathered the burst of the original desktop 3D printing bubble, which saw many companies close up shop. Others, such as MakerBot, were acquired by larger companies. Broader macro issues have caused prolonged issues for much of the competition.

More recently, Formlabs has expanded into SLS (selective laser sintering) technology with its Fuse. As the name implies, the technology uses lasers to sinter powder. According to a recent post from the company’s chief product officer, Formlabs currently “ships more than 50% of all SLS units in the world.” The company also recently acquired two-person SLS startup Micronics.

In recent years, the industry has struggled to broaden 3D printing’s market by scaling the technology for manufacturing. Formlabs has introduced its own high-volume solution (effectively a wall of printers), but the company’s bread and butter has been medical and dental applications like teeth-straightening inserts that require a level of customization not achieved by more traditional manufacturing.